At Marbet Felt, we create innovative products with the use of thermoforming technology. Our love of good design means that we are constantly on the lookout for new forms of expression, while at the same time respecting the natural environment, which is an unlimited source of inspiration for us.

Thermoforming – let’s create something yours!

At Marbet Felt, we have an excellent understanding of our customers’ needs, which we support with the advanced technology and experience of our team. The thermoforming of rPET fibrous fabric, which is created from recycled plastic bottles, allows us to produce durable and attractive structural components with complex shapes.

Thermoforming technology is widely used for example in mass production of various types of decorative elements, furniture or components for automotive and transport industries. Thanks to our automatic and semi-automatic production lines, we can guarantee very high production efficiency and reproducible quality. Our professionalism, commitment and flexibility make us a reliable partner for companies in many industries, including IKEA, with whom we have worked for 30 years.

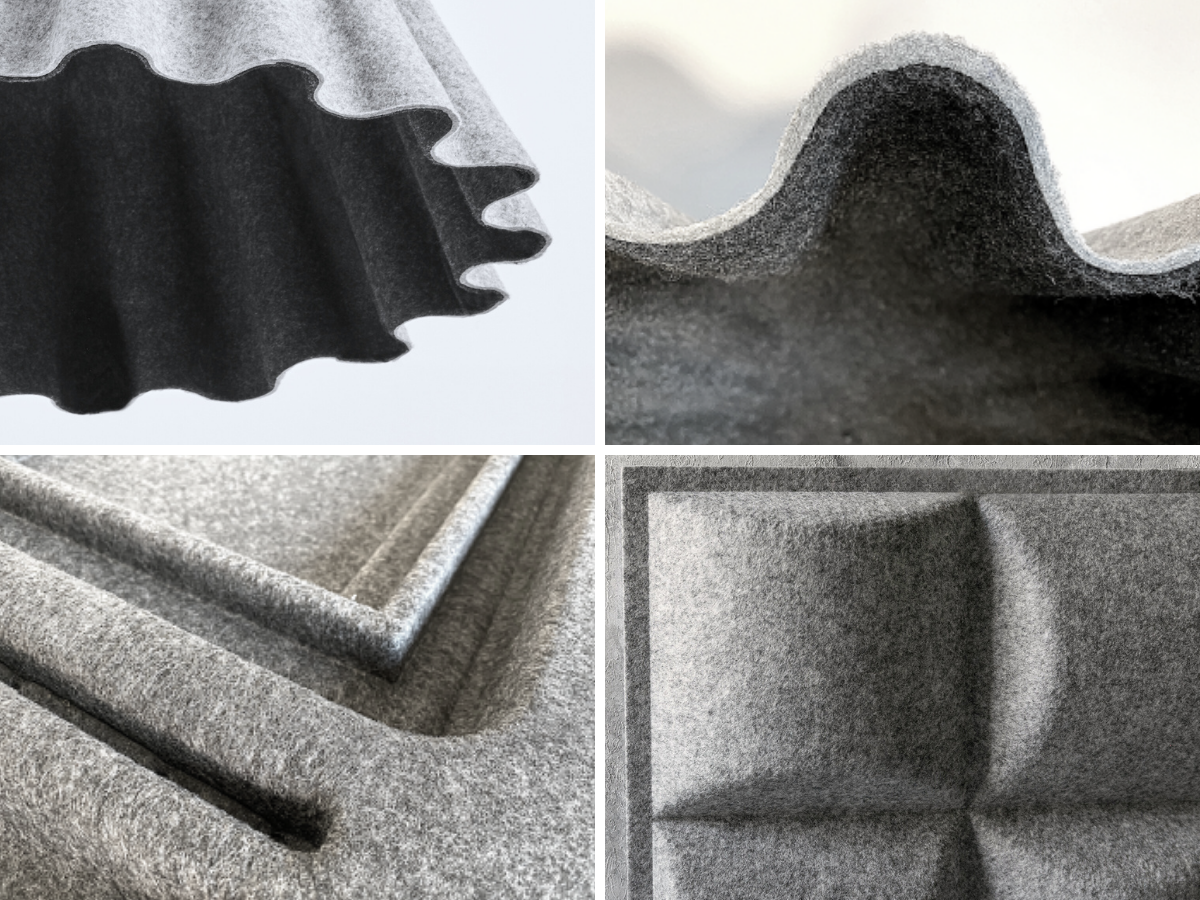

We are not afraid of shapes

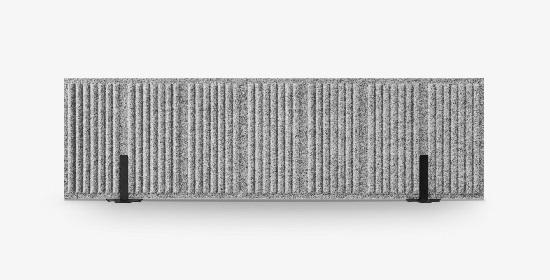

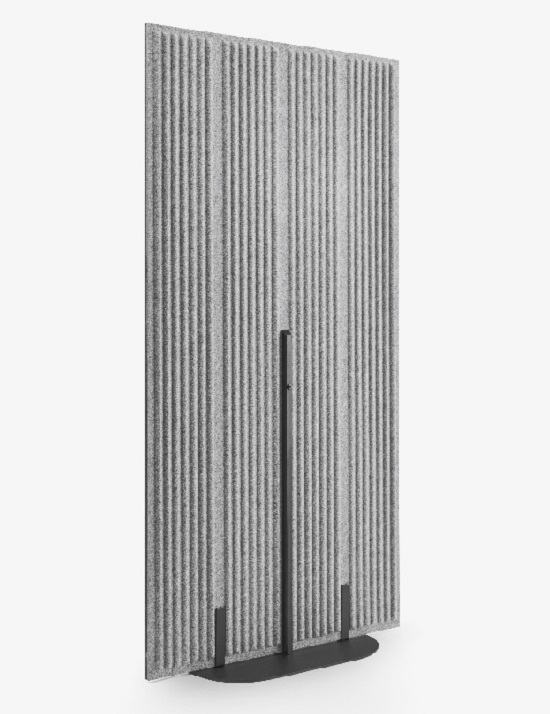

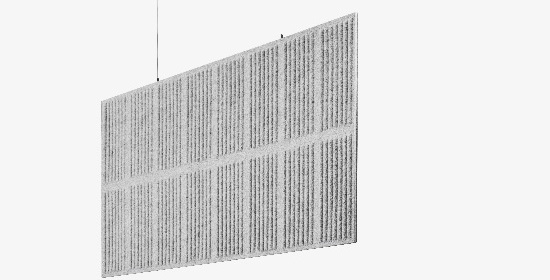

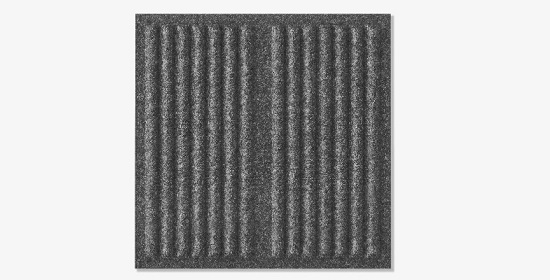

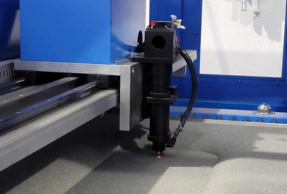

rPET fabric thermoforming is a technology that achieves spectacular results. Thanks to modern production lines, we can precisely form the most complex shapes. Waves, grooves and bends – even very deep ones – are not a problem for us. Our new semi-automatic line also makes it possible to produce large-format products (2100×1400 mm) using a variety of materials, including recycled materials. This is where, among other things, the walls of our soft-filled acoustic booths are built.

The entire production process is overseen by experienced engineers who support our customers with their knowledge from the design stage, to achieve the best possible results.

Why work with us?

Experience

We are a company with more than 40 years of experience in manufacturing, systematically investing in development and new technologies. From the beginning of our operations, we have been creating products under our own brand, but we also produce for external customers. Amongst others, we are trusted by IKEA, with whom we have been working for 30 years. All our projects are comprehensively handled by a team of engineers with extensive experience in product design, modelling and prototype building.

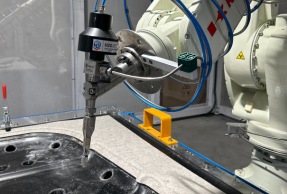

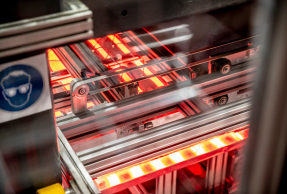

Technology

Thermoforming involves heating fabrics and shaping them in presses. We have been investing in the development of this technology for almost 10 years, expanding our B2B offer with new raw materials and methods. Our state-of-the-art production lines using robots and conveyors allow precise mass production of both complex shapes with high rigidity as well as multi-layered products incorporating different types of surface materials and fillings.

Quality

Thanks to process automation, we achieve reproducible, very good product quality and our exacting standards are based on ISO 9001 and IWAY certification. The robotic technologies we use ensure precise basing and perfect bonding of individual components of multi-layered products. We are also committed to proven sources of raw materials used in production, with an emphasis on innovation and sustainable practices from our suppliers.

Flexibility

Thermoforming technology allows fibrous fabrics with different densities and different proportions of individual fibres to be used for production. This allows us to produce products of different thicknesses and rigidity, hollow or soft-filled, and to use different types of outer layer materials. The production lines we have and the possibility to work in a nested production system allow us to produce in both large series as well as in smaller batches. The raw materials and methods of individual production steps are individually tailored to customer’s needs.

B2B cooperation

We produce for both large chains and smaller customers. Contact us if you are looking for a reliable partner with whom you will implement your project comprehensively – from the conceptual stage to the planned end of your product’s life cycle:

Marcin Kaczmarczyk

Product Manager

tel.: +48 608 479 966

mail: m.kaczmarczyk@marbet.com.pl